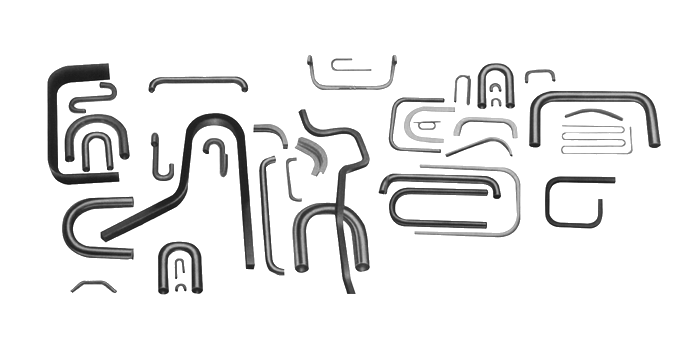

We specialize in the processing of pipes, profiles and angles. Our technological and machine facilities as well as qualified staff enable us to accomplish practically every task. We provide comprehensive services from the design phase to execution.

We have high-performance CNC mandrel benders, manual benders, as well as we make a variety of specialized instruments for specific applications.

We have a high-class machine park, which includes, among others:

• CNC mandrel bending machine - YLM CNC50MS

• CNC mandrel bending machine - BLM Dynamo MR100E

• Molding machine for BLM AST102 pipe ends

Our high-class bending machines, driven electrically by servomotors, give high bending accuracy as well as fast and repeatable production.

Thanks to this, we obtain smooth, oval bending, without wrinkles.

We cut tubes thin (1mm) and thick-walled (5mm)

We form the ends of pipes and profiles - expanding, narrowing and expanding

• Stands and frames

• Elbows

• Handles and handles

• Furniture components

• Chair racks

• Coils and spirals

• Elements of exhaust systems

⌀ diameter

1 x ⌀ diameter

when bending with an interception

7 x ⌀ diameter

We offer laser cutting services in flat sheets. We cut using CNC method in black steel, stainless steel and aluminum.

We cut out any shapes, with 100% repeatability of large series, small series and prototypes

Working range: 4120 mm x 2130 mm

Maximum thickness of sheet metal cutting:

› Structural steel: 20 mm

› Stainless steels: 15 mm

› Aluminum: 10 mm

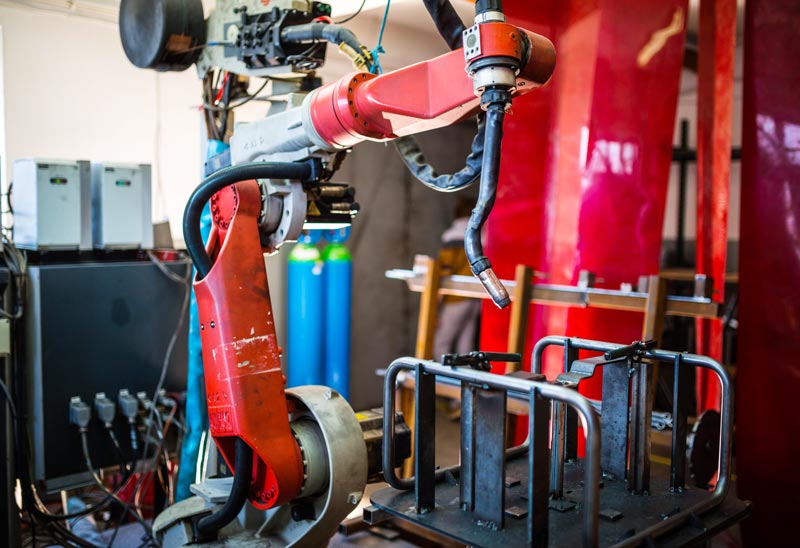

We offer welding services for black steel, stainless steel and aluminum.

MIG / MAG welding in an IGM robotic welding cell with 2 rotary welding tables. KUKA welding arm and Fronius power source

We offer welding of large series of products. We provide full repeatability of performance.

High weld quality - no further machining required.

We use MIG / MAG / TIG manual welding machines for small series and individual parts

We paint metal elements using the powder and wet method

The resulting varnish coating is resistant to corrosion, chemicals, high temperature and mechanical damage.

Dip etching (baths), depending on the material we choose the chemistry and the length of the bath.

Sandblasting, shot blasting,

Crown – electrostatic spraying used for most surfaces, very economical, allowing you to paint gloss paints

Tribo – an electrokinetic spray used for surfaces with complex shapes, ideal for large-scale industrial painting

Through furnace 115 x 125 cm (W x H) designed for large series.

Insert furnace 215 x 200 x 600 cm (W x H x L) designed for large dimensions.

We work hard to meet all expectations, but the reward is satisfaction and loyalty. See our gallery of documents and multimedia.